Quality Assurance & Testing

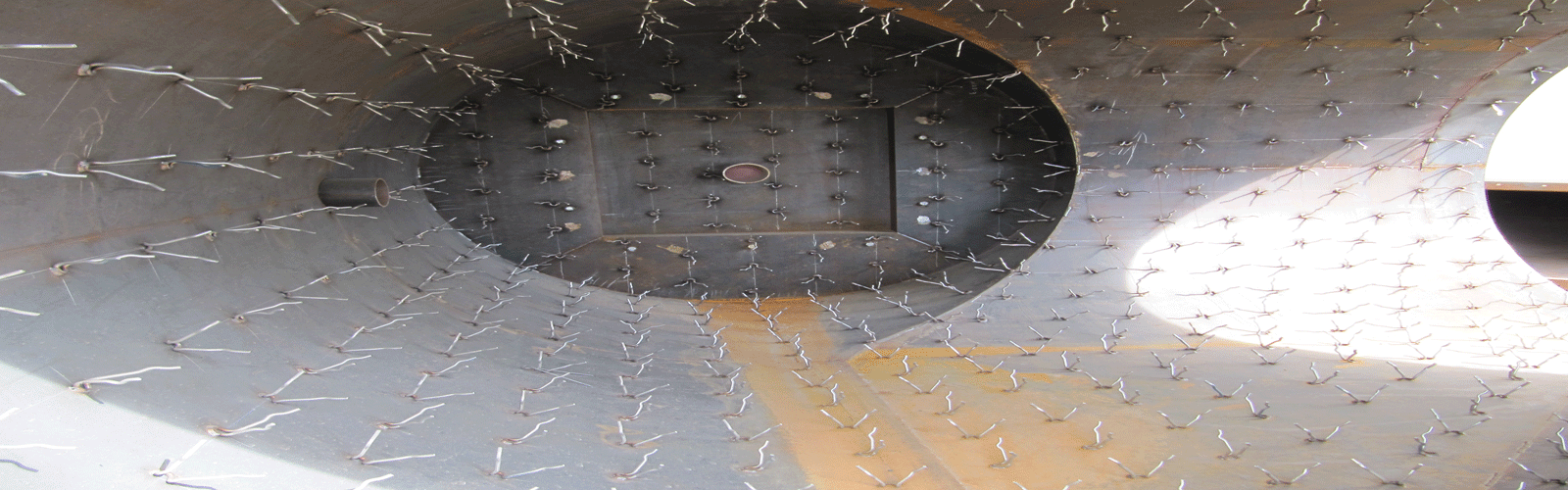

Raghukul Marketing has evolved a Quality Policy that ensures nothing but the best enters or leaves its premises. Starting from raw material sourcing to dispatch of finished products, everything mirrors organization’s quest of quality. Quality at Raghukul is not a tactic brought about by competitive pressures, but a result of desire to its customer the best value for money.

Raw material testing is one of the important factors which determine the quality of the finished product. We test our incoming raw material in NABL approved lab and in the mid of manufacturing process, we perform a Dimensional check on randomly drawn samples from each lot at each stage to ensure a best quality product to our customer.